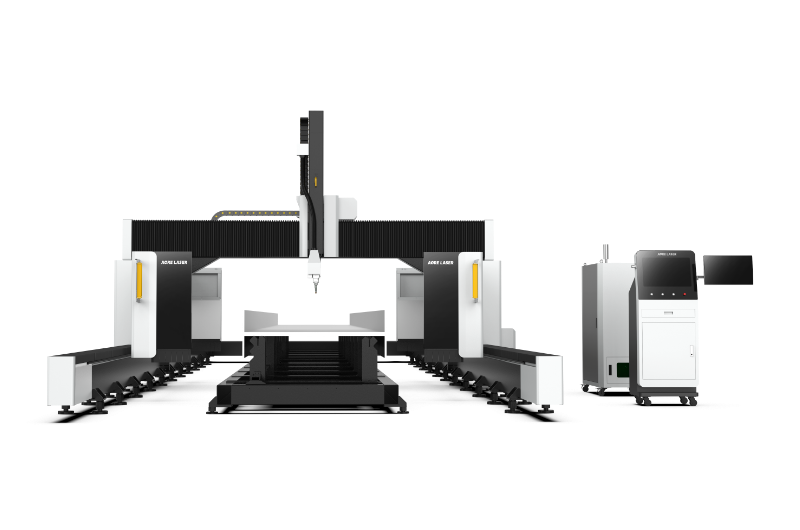

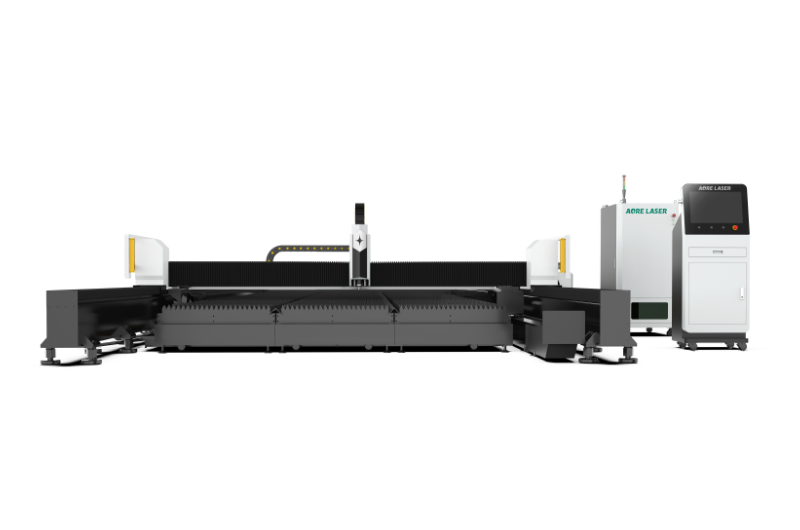

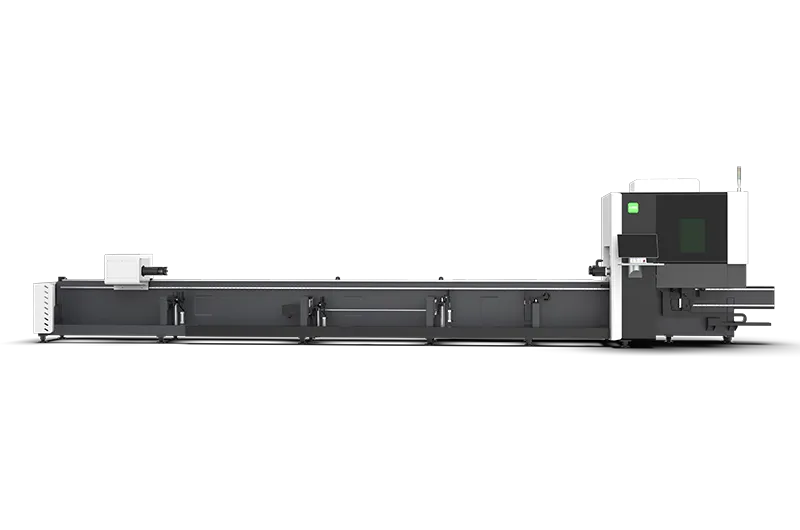

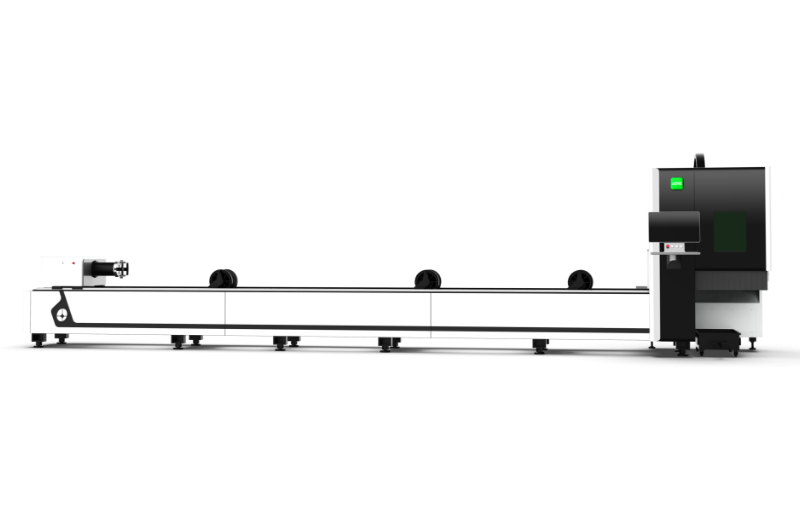

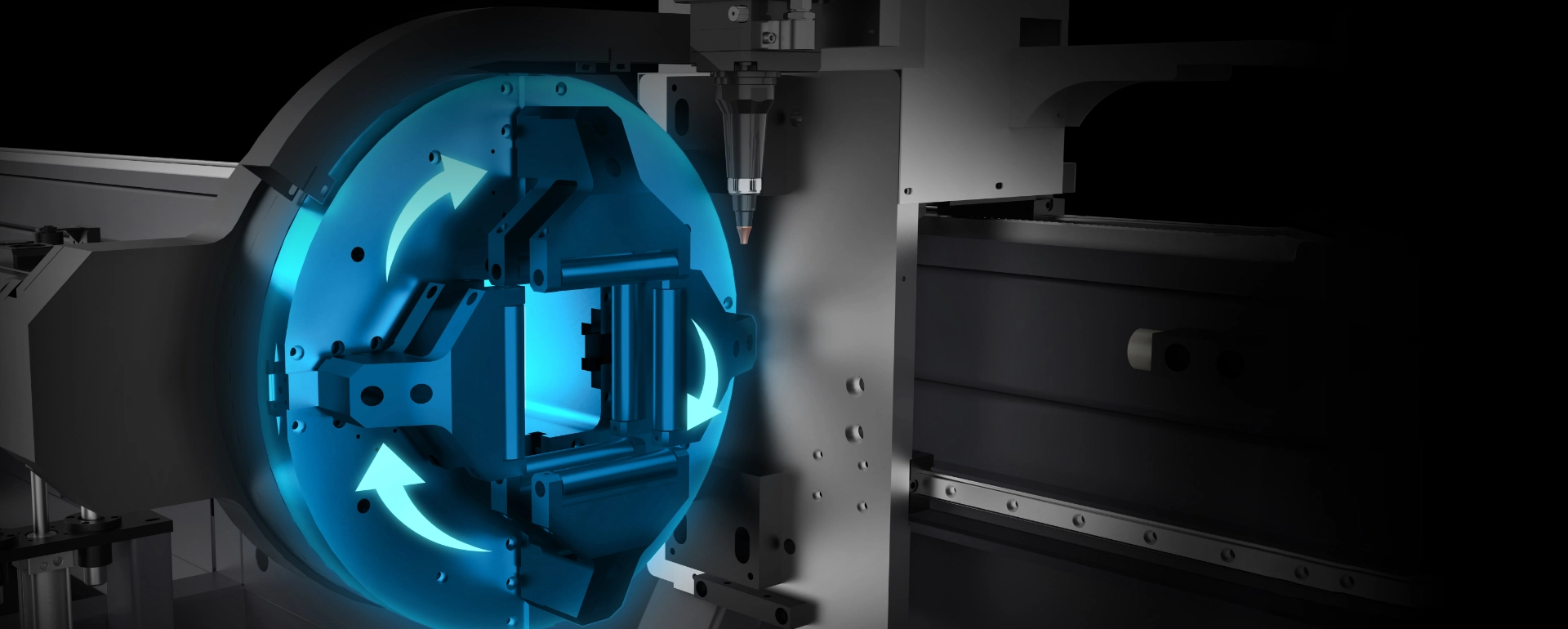

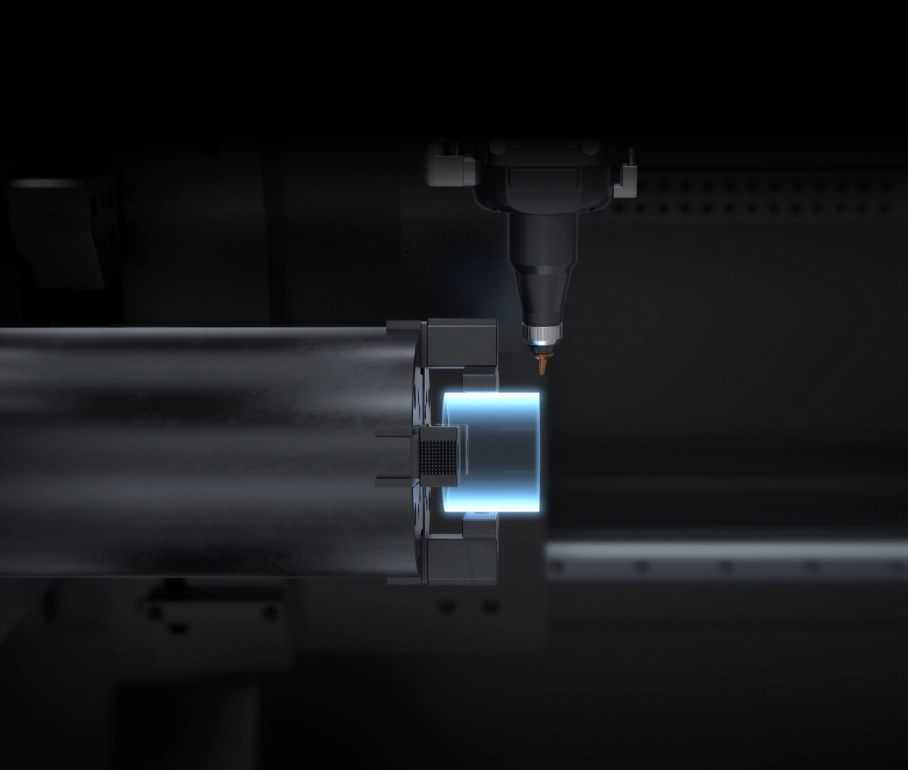

With 2G acceleration and 200 r/min chuck speeds, achieve high-speed tube processing—reducing cycle times, increasing throughput, and accelerating production timelines

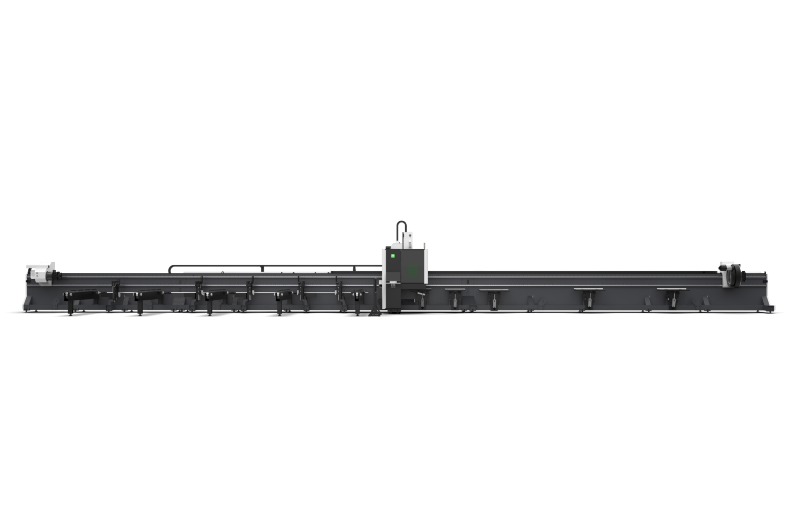

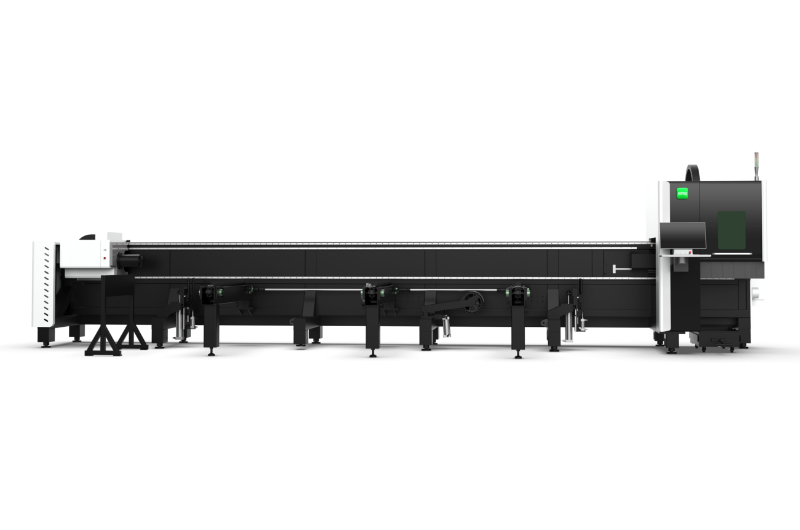

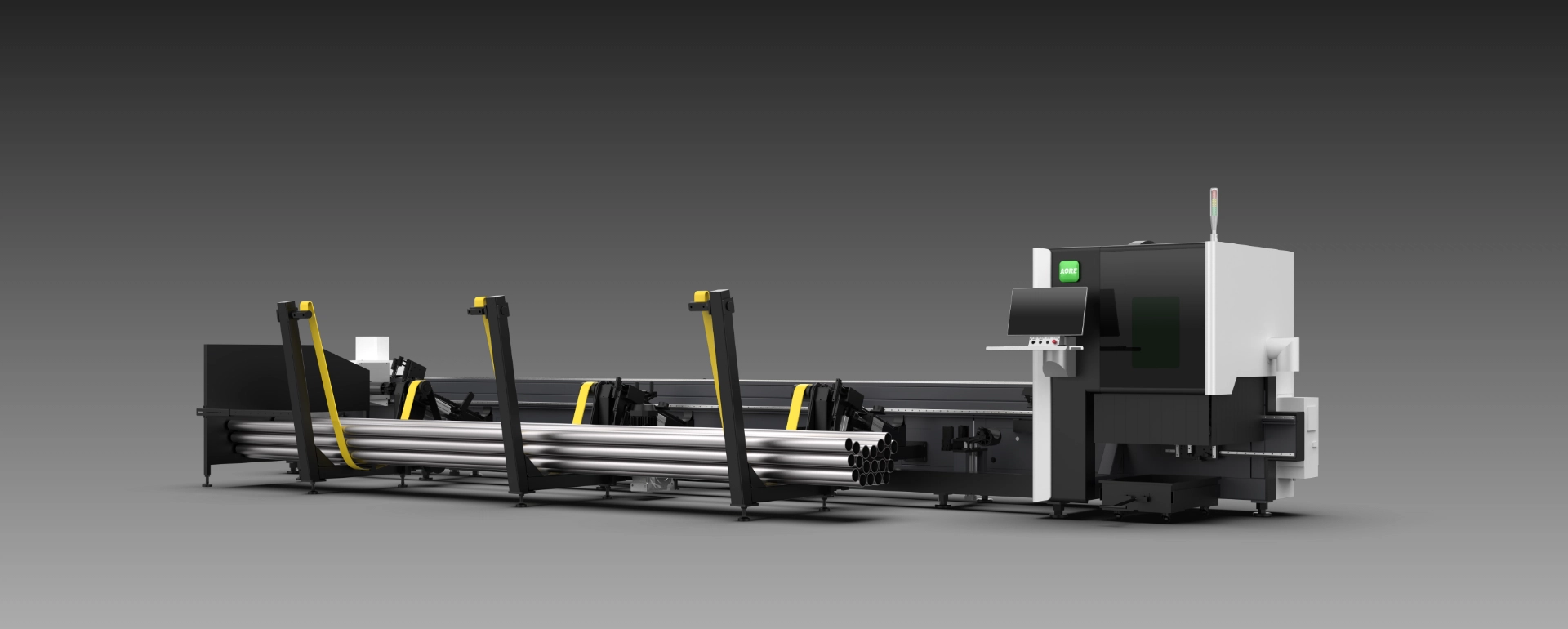

Dual adaptive concave roller support systems maintain tube stability at high speeds, ensuring smooth cutting and pinpoint precision

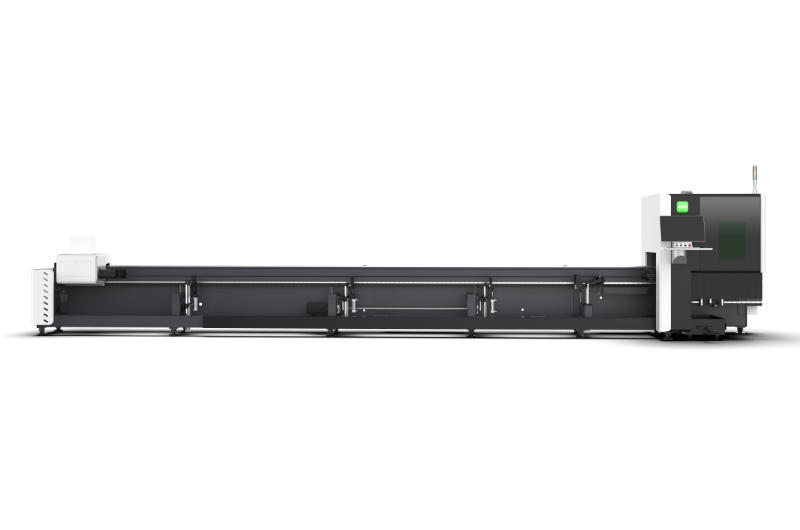

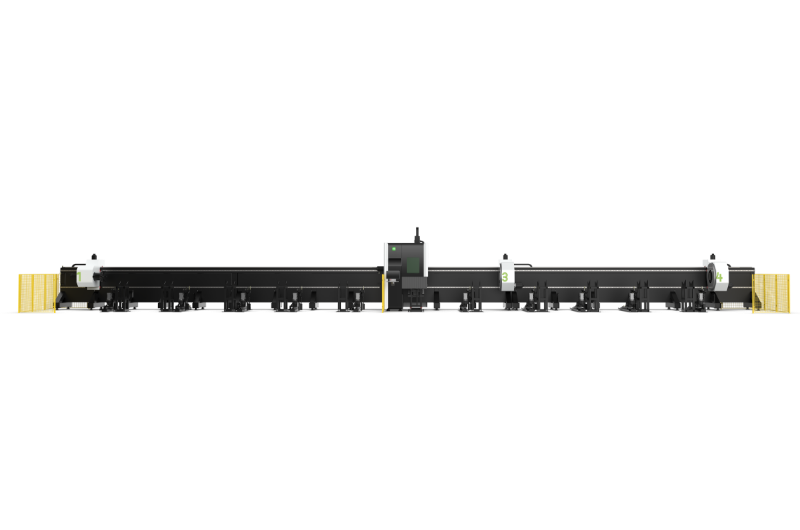

Forward-shifting chuck mechanism minimizes tail waste and material loss, reduces component wear, and boosts overall operational efficiency

Full-process support system stabilizes long tubular materials during loading, cutting, and unloading, ensuring unwavering precision throughout the workflow