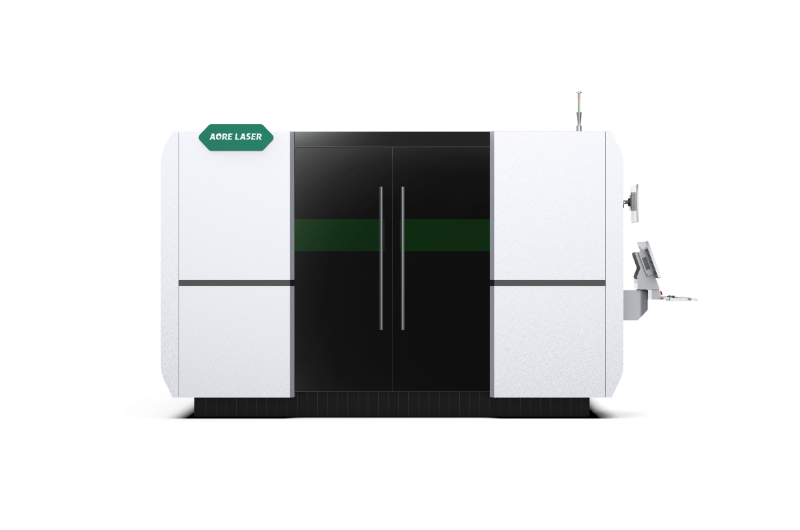

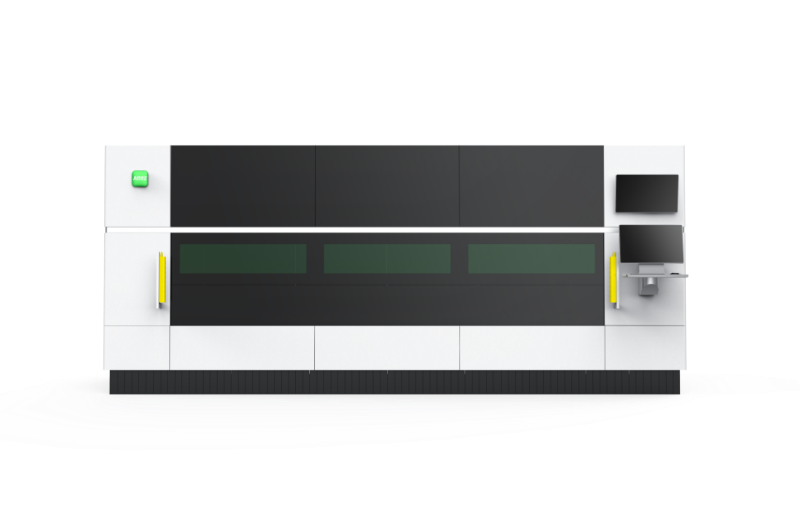

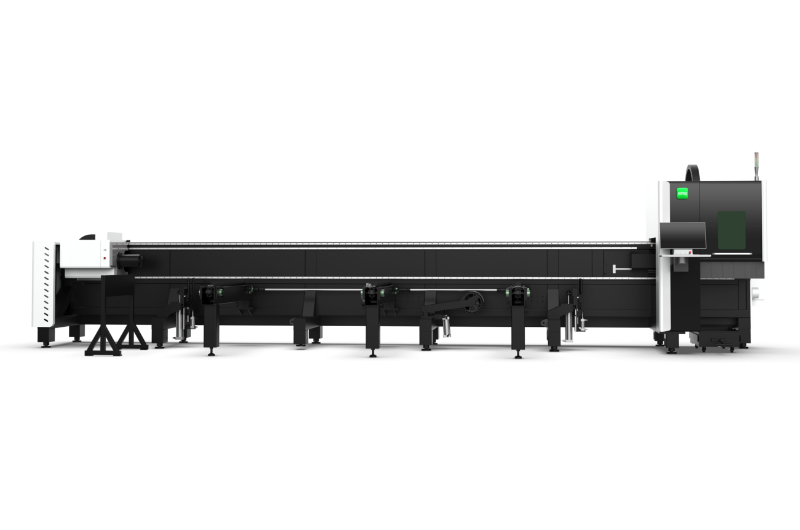

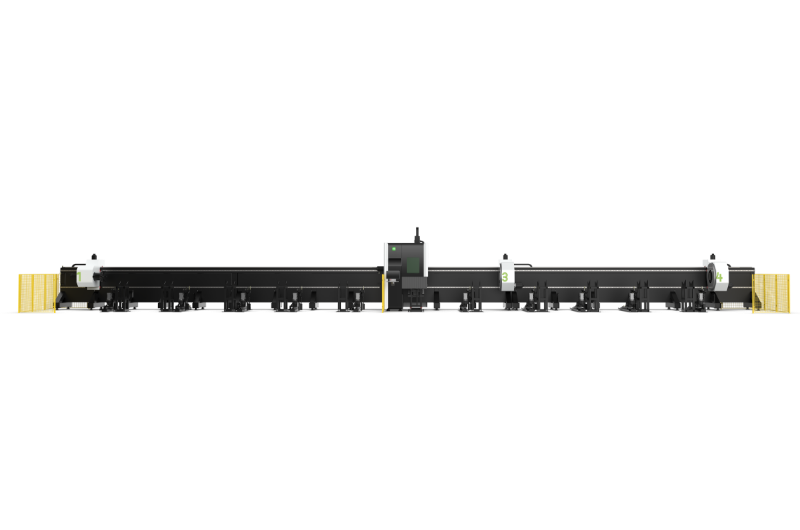

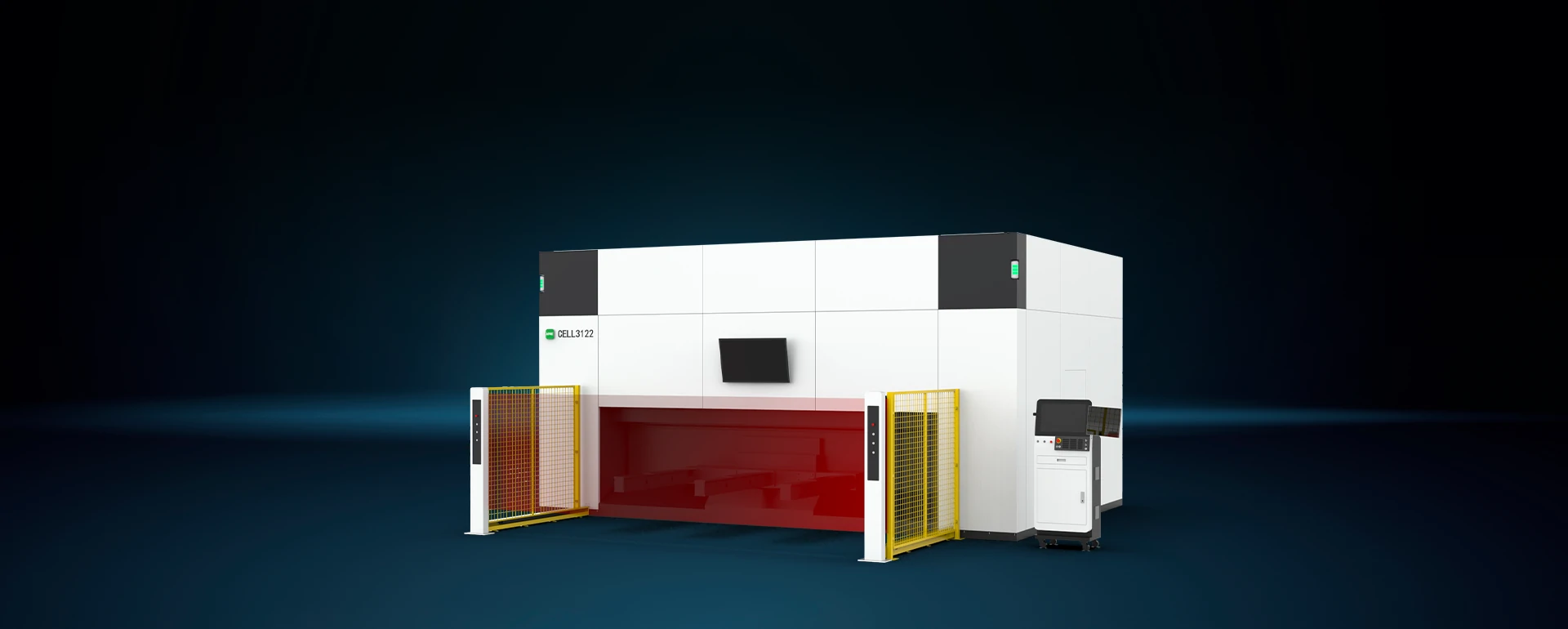

The machine ensures safety through a fully enclosed protective cover and upper/lower dual safety light curtains, creating a comprehensive protection system. It is also equipped with an upper-press lower-suction dual dust removal system, which efficiently removes machining fumes and fully ensures personnel health and equipment safety.

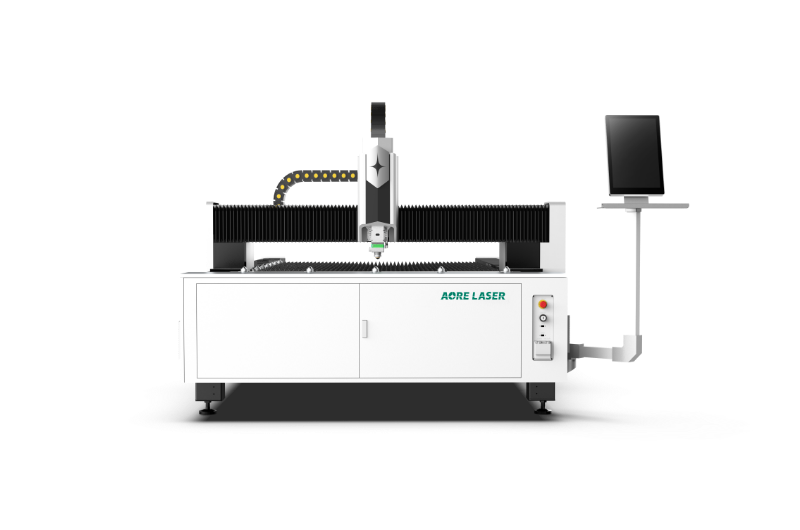

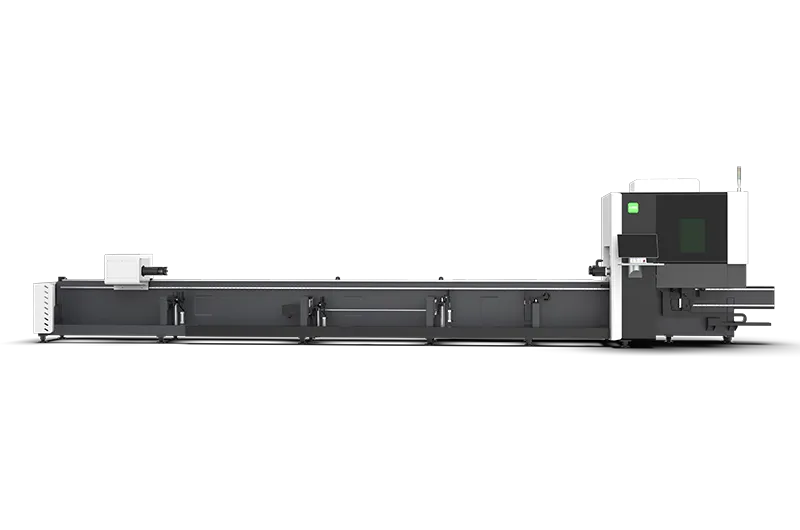

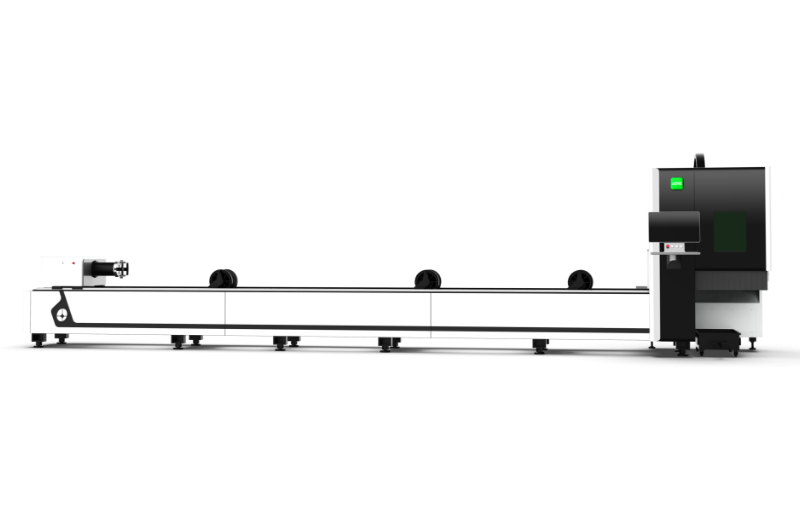

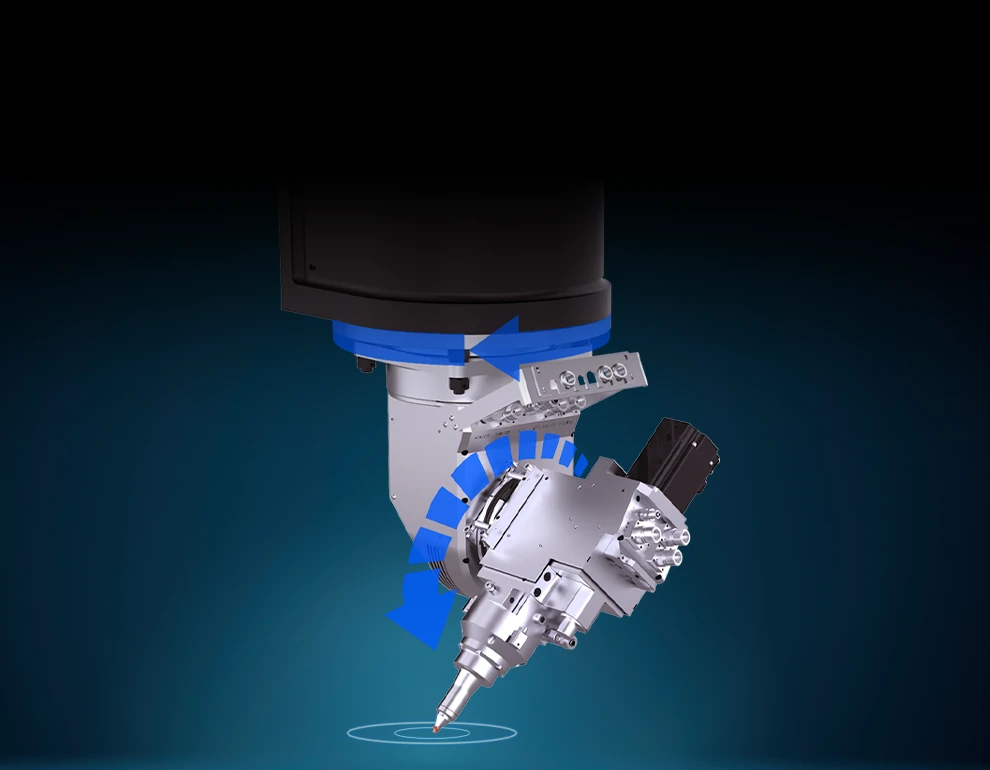

Equipped with a high-speed, high-precision 3D built-in optical path cutting head, it supports 5-axis simultaneous movement. The laser head can rotate infinitely at 360° and achieve ±135° bidirectional swinging, easily handling efficient cutting of various complex curved surfaces and special-shaped materials.

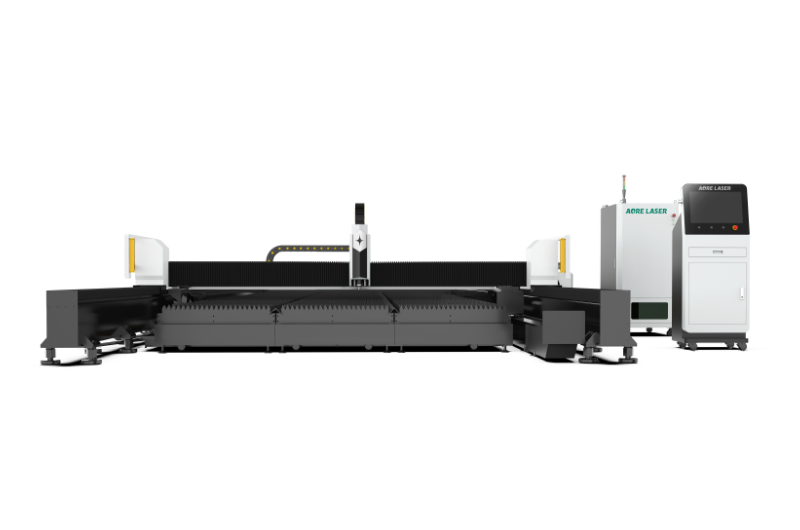

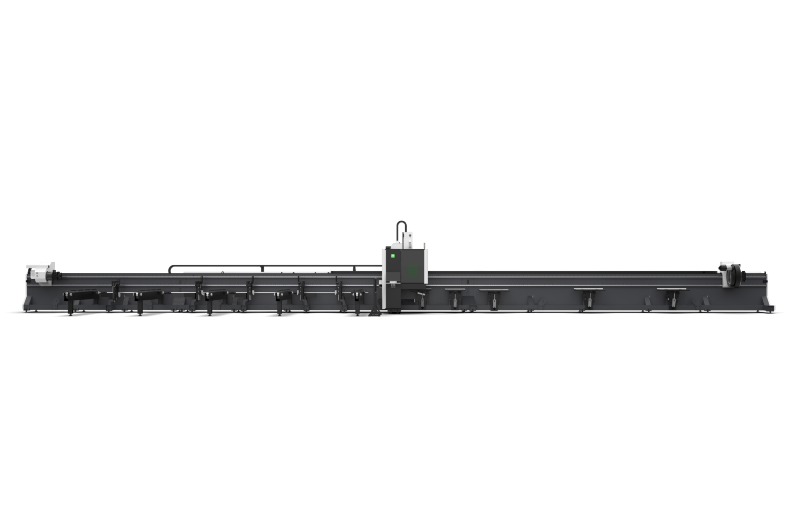

Integrated with the Tebis programming system, it supports intelligent feature recognition and true-to-life cutting simulation. This allows for pre-emptive identification and avoidance of processing risks, drastically reducing manual programming time and boosting overall operational efficiency.

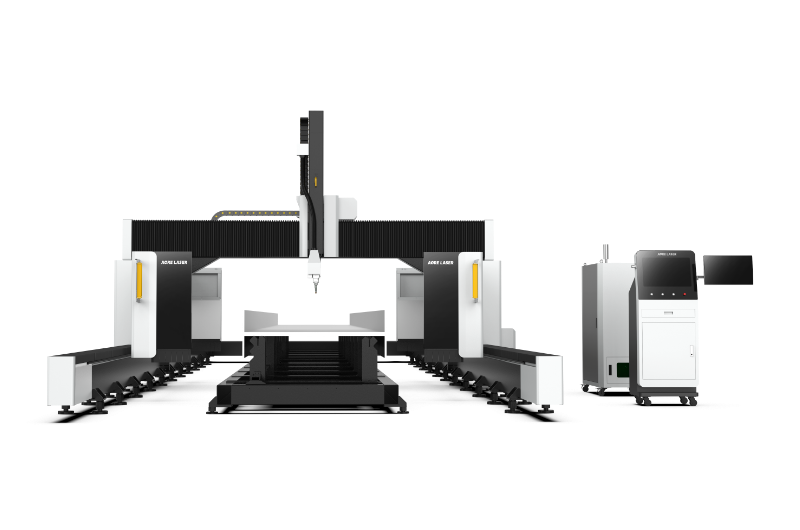

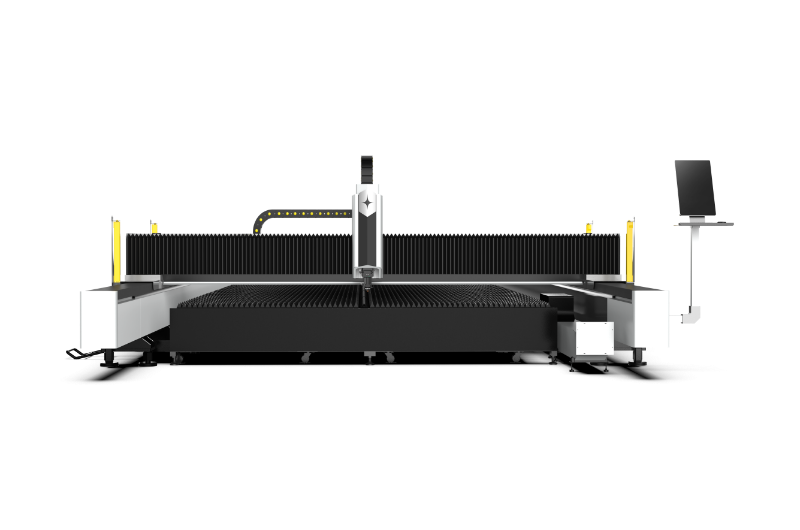

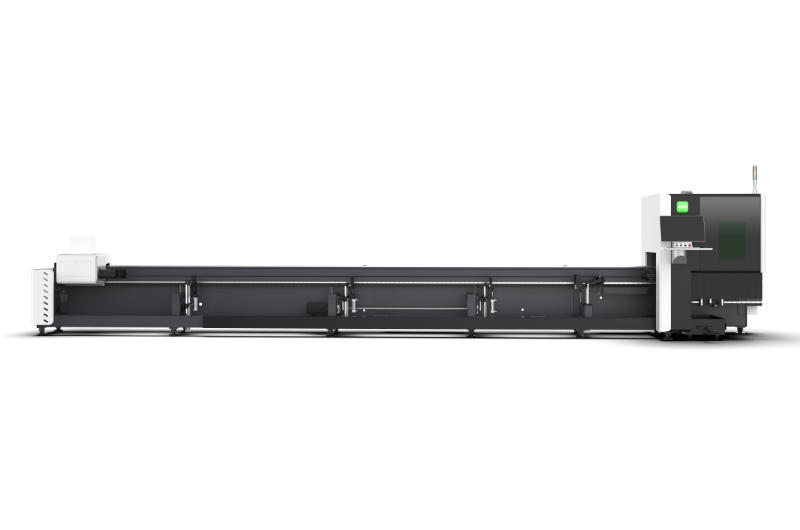

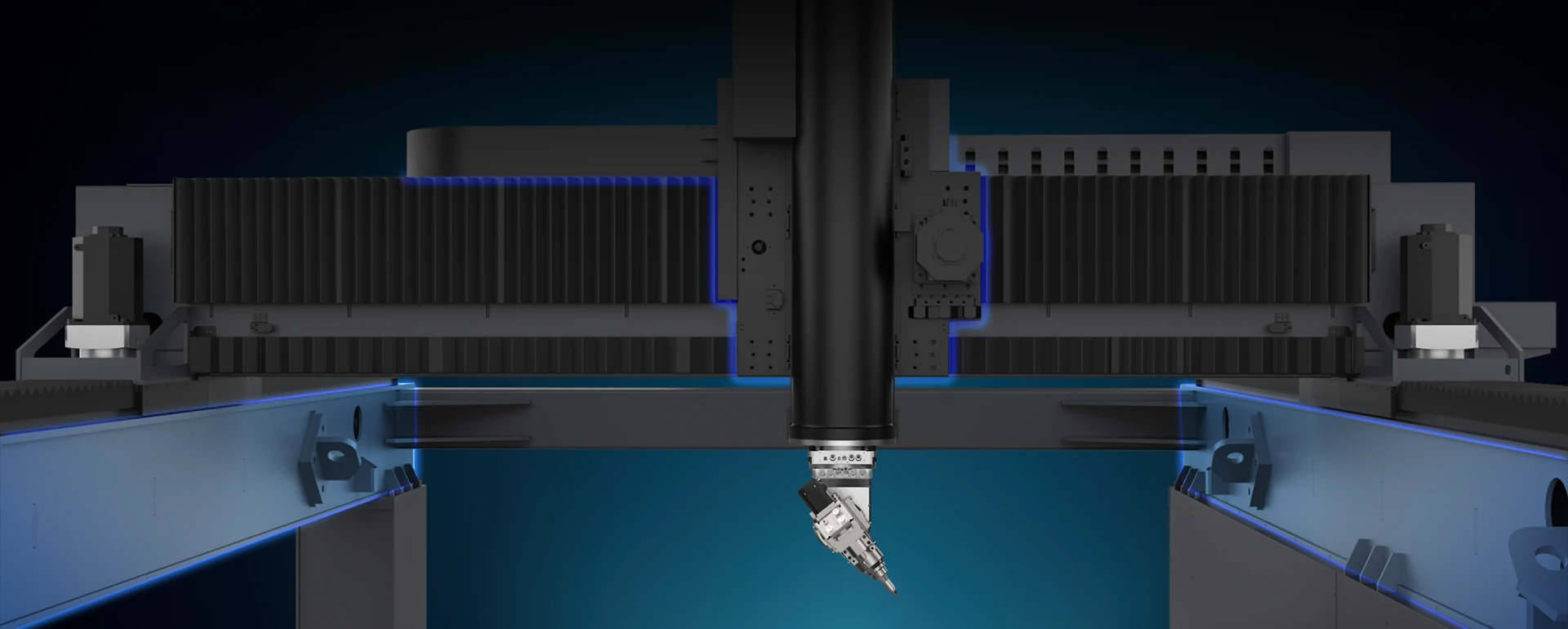

Designed with an overhead gantry structure and a main body integrally welded from high-strength steel plates, this machine significantly enhances overall rigidity and dynamic stability, providing a solid foundation for high-load processing.